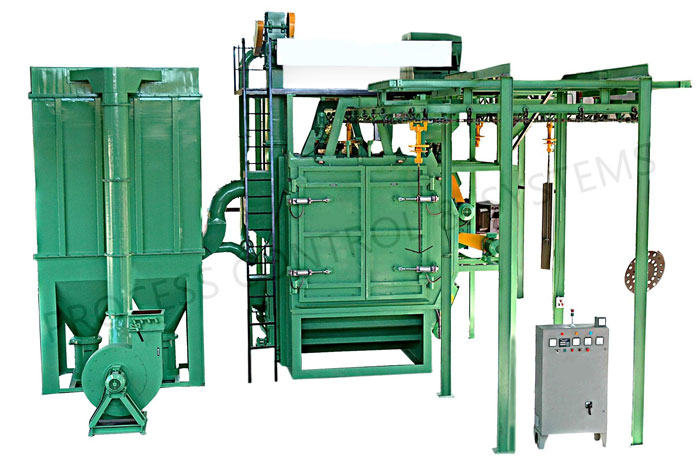

At Process & Systems, we are proud to be a leading supplier and exporter of shot blasting machines in South Africa, serving all major industries including mining, steel fabrication, shipbuilding, automotive, and construction. Our machines are engineered for reliability, precision, and cost-effectiveness; ensuring superior surface treatment for metal, concrete, and alloy components across Johannesburg, Cape Town, Durban, Port Elizabeth, East London, and more.

We specialize in designing and manufacturing machines that meet the unique environmental and industrial demands of South Africa; whether it's dust-heavy inland operations, corrosive coastal atmospheres, or rugged mine and refinery conditions.

South Africa’s Trusted Shot Blasting Equipment Partner

We are trusted by leading South African industries as a top exporter and manufacturer of shot blasting machines, known for delivering superior quality, fast installation, and excellent after-sales support.

Our experience across multiple African markets enables us to deliver machines that are suited for South Africa’s diverse industrial environments, from high-humidity coastal plants to high-dust inland operations.

Built for Harsh Conditions. Backed by Local Support.

Process & Systems supplies customized, high-performance shot blasting machines that deliver consistent surface finish, cleaning, and preparation results. As an internationally certified manufacturer, we supply machines under ISO, CE, and ASME compliance standards, supporting major OEMs and contractors throughout Africa.

What makes us different?

- Engineered for Africa's harsh climates

- Tailored to industrial application and throughput

- Supported by localized training, installation, and parts

- Supplied with 3D layout designs, drawings & operation manuals

- Designed for energy-efficiency and media recycling

Complete Range of Shot Blasting Machines in South Africa

We provide major types of shot blasting machines suited to small parts, batch cleaning, continuous processing, and on-site applications. Here's a complete guide to their applications, configurations, and pricing:

1. Spinner Hanger Shot Blasting Machine

Ideal for cleaning delicate or complex-shaped parts without part collision. Components are suspended and rotated while blast wheels clean uniformly.

Best for: Delicate or complex components requiring high-quality finish

Applications:

- Aerospace turbine parts

- Gear housings and crankshafts

- Medical-grade steel implants

- Valve bodies and alloy castings

Technical Specs:

- Twin hook/Y-shaped hanger system

- 2-6 blast wheels

- Load capacity: 300 kg - 1500 kg

- PLC-operated cycles

- Available in monorail and batch type

Benefits:

- No part-to-part contact

- Uniform blasting for 3D geometries

- Lower media consumption

- Compact design with modular options

Spinner Hanger Shot Blasting Machine

2. Tumblast Shot Blasting Machine

Best for mass cleaning of small to medium parts in batches. Parts tumble continuously for uniform exposure to abrasive blasting.

Best for: Small to medium-sized components in bulk

Applications:

- Foundry parts, forging scraps

- Bolts, screws, spanners, flanges

- Heat-treated components

Technical Specs:

- Barrel/tumble conveyor design

- Abrasive recycling with elevator

- Dust filtration chamber

- Auto-loading (optional)

Benefits:

- Quick batch cycle times

- Ideal for repetitive production lines

- Reduces labor costs

- Uniform cleaning inside & out

3. Table Type Shot Blasting Machine

Used for heavy, large, or awkwardly shaped parts. A rotating table exposes surfaces to multiple blast wheels during cleaning cycles.

Best for: Large and heavy components that can't be tumbled

Applications:

- Dies, molds, pipe fittings

- Engine blocks and heads

- Stone cutting tools

Technical Specs:

- Turntable: 900 mm to 2500 mm

- Load: 300 kg to 200 kg

- Electric turntable and door controls

- Option for dual table for continuous loading

Benefits:

- Complete horizontal coverage

- Gentle cleaning of fragile surfaces

- Perfect for awkward geometries

4. Tunnel Type Shot Blasting Machine

Designed for continuous surface treatment of long structural components like beams and pipes. High-throughput solution with automated conveyors.

Best for: Continuous operations with long structural profiles

Applications:

- H/I beams, tubes, angles

- Steel profiles for fabrication

- Guardrails, wind tower parts

- Construction steel

Technical Specs:

- Variable-speed roller conveyors

- 4 to 12 high-efficiency blast wheels

- PLC auto-control and abrasive recirculation

- Inlet/outlet sealing brushes

Benefits:

- No interruption in production

- Energy-efficient blast wheel configuration

- Automatic shot control for precision blasting

- Integrated dust extraction

5. Portable Shot Blasting Machine

Compact and mobile, perfect for on-site jobs such as bridges, ship hulls, and tanks. Suitable for remote or large-scale surface prep.

Best for: On-site structural cleaning and maintenance jobs

Applications:

- Steel bridges

- Ship hulls

- Storage tanks

- Wind turbines

Technical Specs:

- Hopper capacity: 30L to 150L

- Steel nozzle with tungsten inserts

- Pressure blasting with media recovery

- Mounted on trolley or truck

Benefits:

- Fast setup at remote locations

- Can blast vertical and curved surfaces

- No disassembly required

- Low maintenance

6. Airless Shot Blasting Machine

Propels abrasive using high-speed wheels (not compressed air). Ideal for large flat surfaces like steel plates and concrete slabs with high efficiency.

Best for: Heavy-duty cleaning and concrete profiling

Applications:

- Steel plate cleaning

- Rebar preparation

- Pre-coating treatment

- Cement and tile surfaces

Technical Specs:

- Abrasive speed: up to 80 m/sec

- Dust collection: 3-stage filtration

- Blast wheel power: 5 HP to 60 HP

- PLC automation with safety interlocks

Benefits:

- No need for compressed air

- Saves energy and cost

- Consistent roughness (Ra value)

- Long operational life

Comparison of Shot Blasting Machine Types

Choosing the right shot blasting machine depends on your component size, production volume, finish requirements, and available space. Here's a side-by-side comparison of the most common machine types used across South African industries—from mining and steel to automotive and shipbuilding.

| Machine Type | Best For | Work Capacity | Key Features | Automation | Price Range (ZAR) |

|---|---|---|---|---|---|

| Spinner Hanger | Delicate or complex-shaped parts | 300 - 2000 kg | Rotating hooks, collision-free cleaning, enclosed chamber | Semi/Fully Automatic | R300,000 - R600,000 |

| Tumblast | Small/medium parts in batches | 50 - 1000 kg per batch | Tumbling conveyor, batch cleaning, compact size | Semi-Automatic | R180,000 - R320,000 |

| Table Type | Heavy or irregular-shaped workpieces | 300 - 3000 kg | Rotating turntable, blast from multiple angles | Optional Automation | R240,000 - R480,000 |

| Tunnel Type | Beams, pipes, long profiles (high throughput) | Continuous via roller conveyors | Inline blasting, high-speed production, multiple blast wheels | Fully Automatic | R400,000 - R1,000,000 |

| Portable | On-site field blasting | 30 - 300 L media capacity | Mobile unit, hose-operated, easy setup | Manual | R60,000 - R150,000 |

| Airless | Steel plates, concrete, heavy-duty cleaning | Custom per job | Blast wheels, no air, efficient for large surfaces | Fully Automatic | R320,000 - R800,000 |

Shot Blasting Machine Spare Parts in South Africa

We provide full-service spare part support to all customers across South Africa. Our Johannesburg and Cape Town stock points offer fast shipping and logistics across provinces.

Available Components:

- Impellers, Control Cages, Blast Wheel Assemblies

- Boron Carbide/Tungsten Nozzles

- Manganese Liners & Armor Plates

- Air hoses, Safety Valves, Pinch Valves

- Magnetic separators and media reclaim systems

- Dust Collector Filters, Cartridges & Fans

- Touch Panel HMIs, PLC Controllers

Need help selecting a part? Our technicians can assist with part ID, compatibility checks, and installation.

Why Choose Us - Shot Blasting Experts in South Africa

20+ Years of Blasting Innovation

Supplying custom solutions to global and African clients

Custom-Built Machines

Every machine engineered for your parts, layout & volume

Local Service Team

Field engineers and technicians in SA for fast installation & repairs

Environmental Compliance

Equipped with dust collectors, silencers & energy-saving drives

Global Quality Certifications

All equipment tested under ISO 9001, CE, and BIS

Industries We Serve

We work with leading brands and industries in:

- Automobile & OEMs - Assemblers, dealerships, and refurbishers

- Shipyards & Ports - Ship hull cleaning, dock prep

- Mining & Oil - Crusher maintenance, pipe descaling

- Steel & Foundries - Metal cleaning, shot peening

- Construction - Bridge beams, scaffolding, rebar

- Railways - Bogie, chassis, and track component cleaning

FAQs - Shot Blasting Machines in South Africa

Q1. What’s the difference between air and wheel blasting?

Wheel blasting (airless) uses centrifugal force; air blasting uses compressed air. Wheel blasting is ideal for high-volume industrial jobs.

Q2. Can I use different abrasive media in one machine?

Yes, we offer multi-media systems. Just ensure media hardness, size, and recyclability match your needs.

Q3. Do your machines come with a warranty?

Yes—12-month standard warranty. Extended warranties and AMCs available.

Q4. Do you help with machine placement/layout?

Yes—we provide full 3D layouts, foundation drawings, and positioning guidance.

Q5. Can I automate my existing blasting line?

We offer retrofitting services including robotics, sensors, and conveyer integration.

Manufacturing Shotblasting machine

Process Control & System is a leading shot blasting machine manufacturer and supplier across the globe. Our major operating states and cities in India include Kolkata (W.B), Gandhinagar (Gujarat), Jodhpur (Rajasthan), Faridabad (Haryana).

Supplier of Shotblasting machine

Process Control & system is a leading manufacturer of Shotblasting machine in India and supplier across the world. Our major places where we export and supply our shotblasting machines include )Abu Dhabi (UAE, South Africa, Kenya, Ethiopia, Zimbabwe.