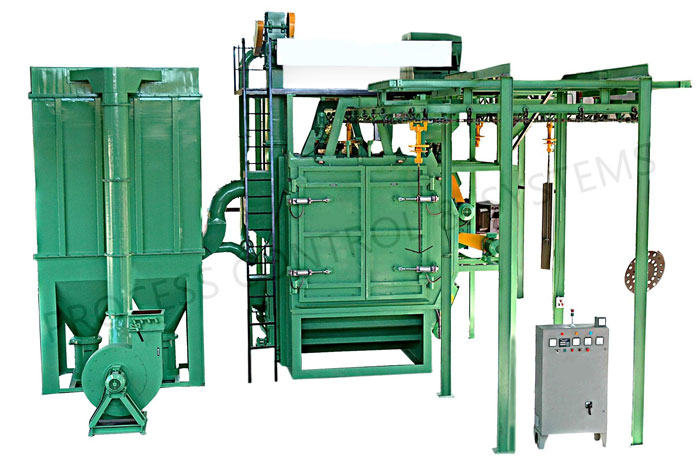

Process & System is a leading shot blasting machine supplier in Kenya, delivering high-performance surface preparation solutions across Nairobi, Mombasa, Kisumu, Eldoret, and other major industrial hubs in East Africa. With decades of expertise, we design and manufacture robust shot blasting machines that meet the unique needs of industries such as construction, automotive, shipbuilding, mining, oil & gas, and metal fabrication.

Our machines are engineered to handle Kenya's diverse climatic conditions-from the humid coastal areas to the dry and dusty interiors-ensuring long-term durability, efficiency, and low maintenance costs.

Trusted Shot Blasting Machine Exporter to East Africa

As a trusted manufacturer and exporter, we have supplied customized shot blasting systems to clients across East Africa, includingKenya, Uganda, Tanzania, and Ethiopia. Our equipment is designed to meet international quality standards (ISO, CE certified) and is supported by local service partners for quick installation, training, and maintenance.

We understand the logistical and environmental challenges in Kenya-whether it's for marine equipment in Mombasa or mining machinery in Kitui-and we provide tailor-made solutions to suit your project's exact requirements.

Our Range of Shot Blasting Machines in Kenya

We offer a complete portfolio of shot blasting machines, each designed for specific applications, production capacities, and operational needs.

1. Spinner Hanger Shot Blasting Machine

- Ideal For: Complex or delicate components that must avoid part-to-part contact.

- Applications: Automotive parts, castings, aerospace components, precision engineering items.

- Benefits: Collision-free blasting, 360° coverage, customizable load capacity, minimal wear.

- Indicative Price (KES): 3,000,000 - 6,000,000.

Spinner Hanger Shot Blasting Machine

2. Tumblast Shot Blasting Machine

- Ideal For: Bulk cleaning of small to medium-sized components.

- Applications: Fasteners, gears, non-critical castings, foundry parts.

- Benefits: High-volume cleaning, space-saving design, excellent for batch processing.

- Indicative Price (KES): 1,800,000 - 3,200,000.

3. Table Type Shot Blasting Machine

- Ideal For: Heavy or awkward-shaped workpieces that cannot be tumbled.

- Applications: Engine blocks, steel structures, molds, pipe fittings.

- Benefits: Fixed or rotating table options, full-surface coverage, crane/forklift loading.

- Indicative Price (KES): 2,400,000 - 4,800,000.

4. Tunnel Type Shot Blasting Machine

- Ideal For: Continuous processing of long or large components.

- Applications: Steel beams, pipes, profiles for fabrication and construction projects.

- Benefits: High production rates, conveyor automation, consistent blasting results.

- Indicative Price (KES): 4,000,000 - 10,000,000.

5. Portable Shot Blasting Machine

- Ideal For: On-site cleaning and maintenance work.

- Applications: Bridges, storage tanks, marine hulls, industrial equipment repairs.

- Benefits: Easy transport, quick setup, versatile for vertical and curved surfaces.

- Indicative Price (KES): 600,000 - 1,500,000.

6. Airless Shot Blasting Machine

- Ideal For: Heavy-duty cleaning of large flat or semi-flat surfaces without compressed air.

- Applications: Steel plates, ship decks, concrete floors, rebar preparation.

- Benefits: Energy-efficient operation, uniform finish, low operational cost.

- Indicative Price (KES): 3,200,000 - 8,000,000.

Shot Blasting Machine Price in Kenya - Quick Overview

| Machine Type | Best For | Automation | Price Range (KES) |

|---|---|---|---|

|

Spinner Hanger |

Complex/delicate parts |

Semi/Fully Auto |

3M - 6M |

|

Tumblast |

Small/medium batch parts |

Semi Auto |

1.8M - 3.2M |

|

Table Type |

Heavy/irregular parts |

Optional Auto |

2.4M - 4.8M |

|

Tunnel Type |

Continuous long items |

Fully Auto |

4M - 10M |

|

Portable |

Field/site work |

Manual |

600K - 1.5M |

|

Airless |

Large heavy-duty surfaces |

Fully Auto |

3.2M - 8M |

Spare Parts & After-Sales Support in Kenya

We stock and supply OEM-quality spare parts for all models, ensuring quick replacements to minimize downtime.

Available Spare Parts Include:

- Blast wheels & turbines

- Tungsten carbide nozzles

- Magnetic separators

- Dust collectors & filter cartridges

- PLCs, sensors, electrical panels

- Shot/grit media and wear liners

Our after-sales support team in Kenya offers:

- Installation & commissioning

- Operator training

- Annual maintenance contracts (AMC)

- Retrofit & upgrade solutions

Industries We Serve in Kenya

- Construction & Infrastructure: Steel fabrication, rebar preparation, concrete surface cleaning.

- Automotive & Engineering: Component cleaning, shot peening, finishing.

- Marine & Shipyards: Hull cleaning, rust removal, coating preparation.

- Mining & Oil: Pipeline cleaning, crusher maintenance.

- Foundries & Railways: Casting cleaning, maintenance blasting.

Why Choose Process Control & System in Kenya

- Proven Performance: Machines designed for Kenyan environmental conditions.

- Tailor-Made Solutions: Built as per your exact production requirements.

- Local Support Network: Quick assistance for breakdowns & maintenance.

- Global Standards: ISO & CE certified manufacturing.

- Energy Efficiency: Advanced designs for reduced power consumption.

Manufacturing Shotblasting machine

Process Control & System is a leading shot blasting machine manufacturer and supplier across the globe. Our major operating states and cities in India include Kolkata (W.B), Gandhinagar (Gujarat), Jodhpur (Rajasthan), Faridabad (Haryana).

Supplier of Shotblasting machine

Process Control & system is a leading manufacturer of Shotblasting machine in India and supplier across the world. Our major places where we export and supply our shotblasting machines include )Abu Dhabi (UAE, South Africa, Kenya, Ethiopia, Zimbabwe.

FAQs - Shot Blasting Machine Supplier in Kenya

Q1: Do you provide installation in Kenya?

Yes, our technical team or partners handle complete installation and training.

Q2: Can you customize machines for my factory space?

Absolutely, machines are designed to fit your production layout.

Q3: Do you offer a warranty?

Yes, all machines come with a standard 12-month warranty.

Q4: Can I get spare parts locally?

Yes, we keep spare parts in stock for quick delivery.

Q5: Do you handle exports to other East African countries?

Yes, we supply to Uganda, Tanzania, Ethiopia, and more.