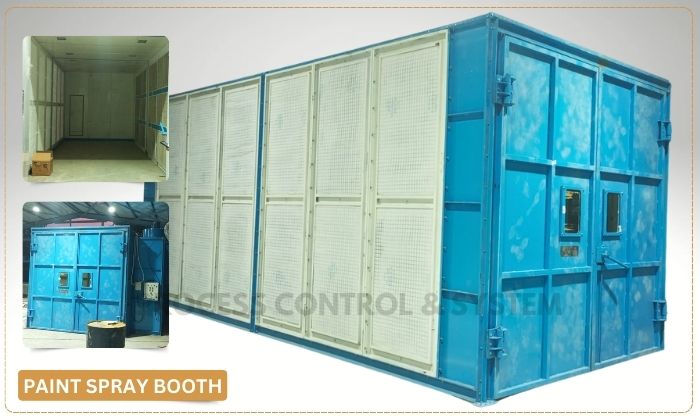

Process Control & System is one of the leading paint spray booth manufacturers in Kolkata, India, offering a comprehensive range of high-quality paint spray booths crafted to meet rigorous international standards. As one of the best paint spray booth manufacturers, we utilize top-tier, quality-tested raw materials under the guidance of our experienced engineers to ensure durable and eco-friendly solutions. Our booths are designed with spray booth technology to enhance both safety and efficiency while requiring minimal maintenance.

Features of Our Paint Spray Booths

Our custom paint spray booths offer a wide array of features, making us one of the top industrial paint spray booth manufacturers. These features include:- No sludge disposal

- Modular construction for ease of installation

- High particulate removal efficiency

- Healthy, pollution-free work environments

- Spray booth ventilation systems powered by centrifugal fans for quiet operation

- Advanced spray booth filters ensuring clean air

- Energy-efficient design and paint booth safety standards

- User-friendly controls for hassle-free operation

Variety of Paint Spray Booths We Manufacture

As one of the most trusted paint booth manufacturing companies, we take pride in producing a variety of custom-designed paint spray booths. Each booth caters to different industrial needs, from automotive to heavy industry, making us a top choice for automotive paint spray booth manufacturers in India.

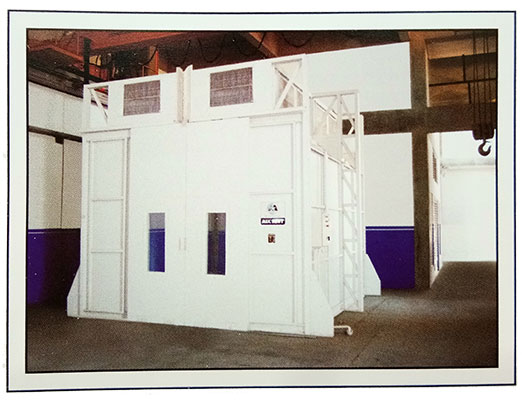

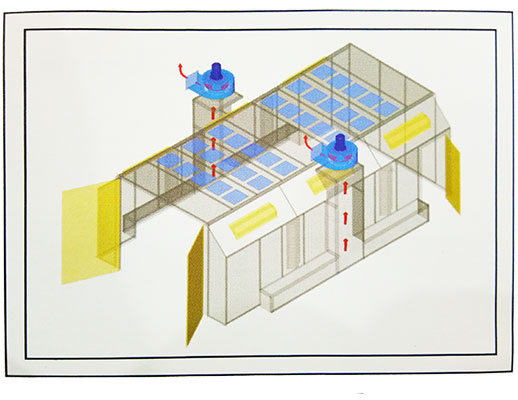

Down Draft Paint Spray Booth

Our Down Draft Paint Spray Booth is designed with a paint booth ventilation system that ensures a clean and efficient environment. The downward airflow pulls overspray towards the floor, away from the object being painted.

Enclosure

A Down Draft Paint Spray Booth is a controlled environment for painting vehicles or objects. The structure includes a floor-level exhaust system where air is drawn from the top and pulled down to the floor through filters, capturing overspray and contaminants. This downward airflow ensures a clean and efficient paint application by directing particles away from the painted surface. The booth is enclosed with insulated panels and ventilation fans to maintain proper airflow. Additionally, it features a lighting system for visibility, ensuring a uniform and quality finish. As a leading paint spray booth manufacturer in Kolkata, India, our construction prioritizes safety, environmental compliance, and optimal painting conditions.

Functions

- Ensures downward movement of paint overspray.

- Prevents particles from escaping the booth.

- Minimizes inhalation exposure to harmful fumes.

- Facilitates even coating application.

- Reduces risks by directing volatile fumes away from ignition sources.

- Captures and filters hazardous materials, complying with regulations.

Benefits

- Superior Ventilation: Efficiently removes overspray and fumes downward, enhancing air quality.

- Enhanced Safety: Minimizes fire risk by directing overspray away from electrical components.

- Improved Finish Quality: Reduces airborne contaminants, resulting in a smoother and more flawless paint job.

- Energy Efficiency: Optimizes airflow for effective paint capture, saving on energy costs.

- Regulatory Compliance: Meets environmental and safety standards, ensuring legal adherence.

- Operator Comfort: Provides a comfortable working environment with reduced exposure to airborne particles.

- Space Optimization: Maximizes floor space by directing contaminants away from the painter.

Product Details:

| Material to be painted | Iron, Steel, Aluminum |

| Air-Flow Direction | Cross-Flow Type |

| Booth Size | Customized according to customer's requirement |

| Material Grade | SS304 |

| Chimney Material | Stainless Steel |

| Height | 80-90 feet |

| Material | Stainless Steel |

Semi-Down Draft Paint spray booth

The Semi-Down Draft Paint Spray Booth combines the best features of down draft and cross draft systems, making it ideal for industries seeking cost-effectiveness with optimal airflow. As custom paint spray booth manufacturers, we design these booths to meet client specifications.

Semi-Down Draft Paint spray booth Details:

| Material To Be Painted | Steel |

| Booth Size | Custom Build |

| Color | Gray -White |

| Heating Mode | Diesel, Infrared Ray, Electric |

| Air-Flow Direction | Cross-Flow Type |

| Body Material | Steel |

| Filter Type | Paint Trap Filters |

Enclosure

A Semi-Down Draft Paint Spray Booth features a ventilation system that draws air from the booth's ceiling and exhausts it through the floor. The booth includes a filtered ceiling structure where fresh air is introduced, creating a downward airflow. This airflow captures overspray particles, directing them toward the floor-level exhaust filters. The filtered exhaust air is then ejected outside. The design minimizes contaminants in the painted finish by preventing overspray from settling on the painted surface. The structure is typically made of galvanized steel panels for durability, and efficient lighting enhances visibility. Such booths are required in automotive and industrial industries for high-quality paint applications.

Functions

- Manages airflow to control overspray and ensure efficient paint application.

- Filters incoming air to maintain a clean painting environment.

- Removes fumes and airborne particles, promoting a safe workspace.

- Provides adequate illumination for accurate painting.

- Balances operator safety with efficient ventilation.

Benefits

- Enhanced overspray control: Semi-Down Draft Paint Spray Booths optimize overspray capture.

- Improved finish quality: Consistent airflow ensures even paint distribution for a smoother finish.

- Operator safety: Efficient extraction of fumes and particles protects workers from harmful exposure.

- Energy efficiency: Balanced airflow reduces energy consumption, lowering operational costs.

- Easy maintenance: Accessible filters and components simplify booth upkeep, minimizing downtime.

- Regulatory compliance: Meets industry standards for environmental and safety regulations, ensuring legal compliance.

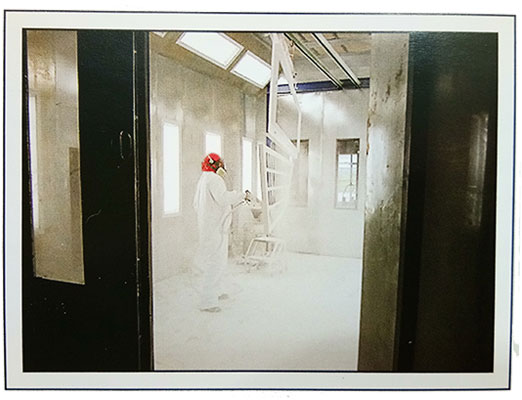

End Draft Paint Spray Booth

The End Draft Paint Spray Booth directs airflow from one end of the booth to the other, efficiently removing overspray and fumes. This booth is highly regarded for its balance of performance and affordability, making us one of the best industrial spray booth suppliers.

Product Details:

| Color | White |

| Material To Be Painted | Wood |

| Air-Flow Direction | Fully Undershot Type |

| Heating Mode | Electric |

| Material | Stainless Steel |

| Surface Finish | Painted |

| Height | up to 7 feet |

Enclosure

For the End Draft Paint Spray Booth, we typically make a robust frame with galvanized steel panels forming the enclosure. The booth includes an exhaust fan at one end to create a controlled airflow from the front to the back. Filters, such as intake and exhaust filters, ensure air purity. The interior features high-efficiency lighting and a grated floor to facilitate overspray collection. Additionally, a control panel manages ventilation and temperature. The booth we design and manufacture adheres to safety standards, incorporating fire-resistant materials.

Functions

- Captures overspray, preventing paint particles from spreading.

- Purifies and circulates air, removing contaminants for a clean finish.

- Ensures proper air circulation and exhaust for a safe working environment.

- Provides optimal visibility for accurate painting.

- Regulates temperature for ideal paint application and drying.

- Minimizes fire hazards and protects workers from harmful fumes.

Benefits

- Efficient Painting: End Draft Paint Spray Booth ensures optimal airflow for even paint distribution.

- Worker Safety: The booth effectively captures and filters paint overspray, reducing health risks.

- Environmental Compliance: Enhanced filtration minimizes emissions, meeting regulatory standards.

- Quality Finish: Consistent airflow prevents contaminants, ensuring a smooth and professional paint finish.

- Cost Savings: Reduced overspray and efficient filtration lead to lower paint consumption and maintenance costs.

- Quick Drying: Proper ventilation expedites paint drying, improving productivity in automotive and industrial applications.

Down Draft Wet Paint Spray Booth

Our Down Draft Wet Paint Spray Booth uses water curtains to trap paint particles, ensuring eco-friendly operations. We are recognized among eco-friendly paint spray booth manufacturers for our commitment to sustainable and clean working environments.

Enclosure

The Down Draft Wet Paint Spray Booth utilizes a downward airflow system, pulling contaminated air through the floor and expelling it through filters. The wet paint application involves water curtains or water walls to capture overspray, minimizing airborne particles. A water recirculation system is employed to maintain optimal humidity levels, enhancing paint adhesion and reducing airborne contaminants. The filtered exhaust air is then expelled safely. The booth design ensures efficient ventilation, containment, and environmental compliance, creating a controlled environment for precise and high-quality wet paint application in various industries.

Functions

- Guides overspray and fumes downward.

- Prevents paint particles from escaping.

- Captures and filters paint particles.

- Removes contaminated air.

- Minimizes fire hazards.

- Reduces dust and debris for a smoother paint job.

- Manages and filters harmful emissions.

Benefits

- Efficient overspray capture: Down Draft Wet Paint Spray Booths ensure effective containment and removal of overspray, enhancing paint application precision.

- Improved air quality: The downward airflow minimizes the risk of airborne contaminants, creating a safer and healthier working environment.

- Reduced fire hazard: Wet suppression systems decrease the likelihood of ignition, enhancing overall safety.

- Superior finish quality: The controlled environment minimizes dust and debris, leading to a smoother and more consistent paint finish.

- Environmental compliance: Wet filtration systems contribute to eco-friendly operations by containing and managing potentially harmful emissions.

Water Curtain Paint Spray Booth

The Water Curtain Paint Spray Booth offers a cost-effective solution for industrial painting, using water to capture overspray. As one of the top paint spray booth manufacturers, we ensure these booths are designed with minimal environmental impact and comply with all paint booth safety standards.

Product Details:

| Width | 2500 mm |

| Depth | 2000 mm |

| Height | 2200 mm |

| Blower | 3 HP |

| Water pump | 0.5 HP |

Enclosure

A Water Curtain Paint Spray Booth consists of a three-sided chamber with water curtains and a paint application area. The booth utilizes water curtains to capture overspray and paint particles, preventing their release into the environment. The structure typically includes a water reservoir at the bottom, a pump system to circulate water, and an exhaust system to maintain airflow. A series of filters may be incorporated to enhance particle removal. This design ensures that overspray is contained within the water curtain, reducing environmental impact and ensuring a cleaner and safer workspace for paint application processes.

Functions

- Water curtain paint spray booths use a curtain of water to contain overspray and paint particles.

- The water captures and filters out paint particles, preventing environmental pollution.

- Efficient air circulation ensures a safe working environment for operators.

- Water curtains reduce the risk of fire by suppressing flammable vapors.

- Lower maintenance costs compared to traditional filtration systems.

Benefits

- Enhanced Safety: Minimizes fire risk by containing and suppressing overspray.

- Environmental Compliance: Efficiently captures and filters paint particles, reducing air pollution.

- Quality Finishes: Prevents contaminants from affecting paint jobs, ensuring a smooth and flawless finish.

- Worker Health: Shields operators from harmful fumes and particles, promoting a healthier work environment.

- Cost Savings: Reduces paint waste and cleanup efforts, optimizes resources, and improves overall operational efficiency.

Why Choose Us as Your Paint Spray Booth Manufacturer?

At Process & System, we are dedicated to being the best paint spray booth manufacturers in the industry by delivering high-performance, reliable solutions. Our custom-designed paint spray booths for industrial use are equipped with the latest spray booth technology, ensuring long-lasting durability and efficiency. We are also known for providing comprehensive paint spray booth installation services.

Our Expertise in Paint Booth Manufacturing

Our expertise as one of the top-rated paint spray booth manufacturers for custom solutions allows us to meet diverse client requirements across sectors. Whether you're looking for affordable paint spray booth manufacturers near me or industrial paint booth manufacturing process explained, we are here to assist with every step of the project.