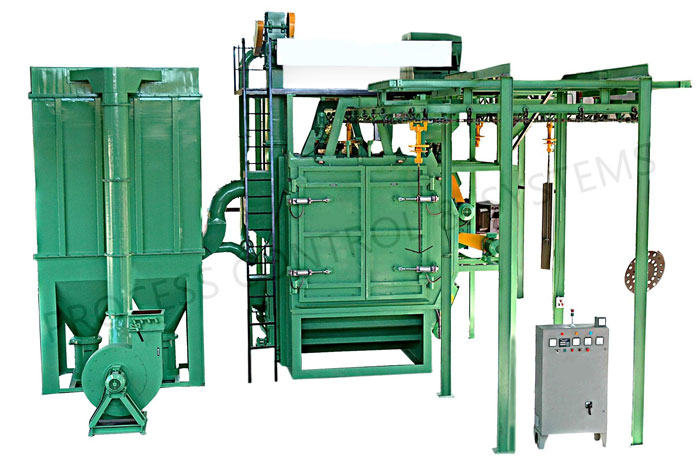

A leading manufacturer of advanced hanger-type shot blasting machines designed to elevate your surface preparation and finishing processes. Our commitment to innovation and quality ensures that our machines deliver unparalleled efficiency and reliability across diverse industrial applications.

Discover the Power of Our Hanger Type Shot Blasting Machine

As a hanger-type shot blasting machine manufacturer, Process & System integrates cutting-edge technology with robust engineering to meet the stringent demands of modern manufacturing. Whether you operate in the automotive, aerospace, foundries, construction, or shipbuilding industries, our airless shot blasting machines are tailored to optimize productivity and enhance product quality.

Types of Hanger Type Shot Blasting Machines

When it comes to industrial shot blasting machines, finding the right hanger type can significantly impact your operations. Here’s a comprehensive look at three types that any hanger type shot blasting machine manufacturer or supplier should consider.

- Closed-loop Hanger Shot Blasting Machine: If efficiency and thorough cleaning are your priorities, look no further than the closed-loop hanger shot blasting machine. Designed with a conveyor system of chain-driven trolleys, this machine ensures optimal placement and movement of components through the blast chamber. High-velocity abrasive media from strategically located blast wheel stations guarantee even blasting on all sides. This makes it a top choice for manufacturers looking to streamline their production processes.

- Y-type Hanger Shot Blasting Machine: Flexibility meets precision with the Y-type hanger shot blasting machine. It features automatic or manual loading onto trolley-mounted hangers, followed by a dynamic blasting process. The hanger rotates in both clockwise and anti-clockwise directions, ensuring thorough cleaning of components. After blasting, the hanger moves out effortlessly for unloading, allowing for continuous operation and minimal downtime.

- Door-type Hanger Shot Blasting Machine: Versatility is the name of the game with the door-type hanger shot blasting machine. Components are hung on the machine’s door or gate, providing 360-degree access for blasting. Whether loaded manually or pneumatically, the door-type machine delivers consistent results. After blasting, simply open the door for easy access to cleaned components, making it ideal for manufacturers prioritizing efficiency and ease of use.

As a hanger type shot blasting machine manufacturer or supplier we know choosing the right machine can enhance productivity and efficiency in your operations. Each type offers unique benefits, from streamlined cleaning cycles to versatile loading options, ensuring you find the perfect fit for your industrial needs. Discover more about these machines be it portable shot blasting machine or tumblast shot blasting machine, today to elevate your manufacturing processes.

Key Features of Hanger Type Shot Blasting Machine

Some of the primary features of hanger shot blasting machines are:

- Uniform Cleaning: Ensures even shot blasting coverage across all surfaces of the workpieces.

- High Productivity: Can handle large volumes of workpieces per hour, optimizing production output.

- Dust Collection System: Includes efficient dust extraction and separation systems for a cleaner working environment.

- Automation Capability: Often equipped with automated loading and unloading systems for streamlined operation.

- Durability: Constructed with robust materials and components for long-term reliability in industrial settings.

- Safety Features: Includes protective measures such as interlocks and emergency stop buttons to ensure operator safety.

- Energy Efficiency: Designed to minimize energy consumption while maximizing operational effectiveness.

- Easy Maintenance: Accessible components and straightforward maintenance procedures for reduced downtime.

Specifications of Hanger-type Shot Blasting Machines

Process & System offers a range of hanger-type shot blasting machines with customizable features to suit specific production needs:

- Model Variants: Choose from different models offering various capacities and configurations.

- Dimensions: Tailor machine dimensions to fit your workspace layout and operational requirements.

- Capacity: Efficiently process batches of components ranging from small parts to large assemblies.

- Power Requirements: Designed for energy efficiency without compromising blasting performance.

- Operating Speed: Adjustable blasting speeds to optimize results based on material type and application.

- Blast Wheel Details: Utilize advanced blast wheel technology for precise control over shot distribution and impact.

Technical Specification Sheet Of Airless Shot Blasting Machine-Hanger Type

| Model Name | Blast Wheel | Shot Flow Rate (kg./Wheel/Hour) |

Load Carrying Capacity of Hanger (kg.) |

Wheel Size & Motor (HP) |

Total Power Required (HP) |

|---|---|---|---|---|---|

| ASH-1 | 2 | 3000 | 300 | 121⁄2 x 5 | 14.5 |

| ASH-2 | 2 | 3000 | 300 | 121⁄2 x 5 | 14.5 |

| ASH-3 | 2 | 5000 | 300 | 121⁄2 x 7.5 | 23 |

| ASH-4 | 2 | 3000 | 300 | 121⁄2 x 5 | 14.5 |

| ASH-5 | 2 | 5000 | 300 | 121⁄2 x 7.5 | 23 |

| ASH-6 | 2 | 3000 | 300 | 121⁄2 x 5 | 14.5 |

| ASH-7 | 2 | 5000 | 300 | 121⁄2 x 7.5 | 23.5 |

| ASH-8 | 2 | 3000 | 300 | 121⁄2 x 7.5 | 23.5 |

Cost of Hanger Type Shot Blasting Machine

Investing in a hanger type shot blasting machine involves considering several factors, including machine specifications, customization options, and operational requirements. Process & System offers competitive pricing tailored to your specific needs. The hanger type shot blasting machine cost ranges between INR 10 lakhs to INR 25 lakhs. Contact us today for a detailed quote based on your project requirements.

How It Works

In the first step, workpiece holders hang directly from the rotating hook of the running gear, positioning the workpieces in front of the shot-blasting machine. A mechanism automatically feeds the workpieces into the initial blasting position.

Once the blasting program starts, the machine's door closes automatically and locks electro-pneumatically. As the workpieces rotate, they undergo blasting at three different stations with preset blasting durations. The blasting abrasive undergoes continuous cleaning and reuse, facilitated by an abrasive metering device from the storage.

At the end of the blasting cycle, the turbines come to a halt, the machine door opens automatically, and the suspended workpieces revert to their original position. A fan unit generates the necessary partial vacuum for dust-free operation, and extracted air passes through a specialized filter unit within the shot blasting machine.

Our hanger-type shot-blasting machines operate through a streamlined process:

- Loading: Components are securely hung on the conveyor system within the blast chamber.

- Blasting: Powerful blast wheels propel abrasive media onto surfaces, effectively removing contaminants and preparing them for subsequent processes.

- Unloading: Cleaned components are unloaded from hangers, ready for inspection, coating, or further processing.

Applications of Hanger Type Shot Blasting Machine

Process & System’s hanger-type shot blasting machines excel in various critical applications, including:

- Surface Cleaning: As a hanger type shot blasting machine manufacturer, you can highlight how your equipment effectively removes rust, scale, paint, and other contaminants from metal surfaces. This capability ensures that the parts processed with your machines meet high standards of cleanliness and preparation for further manufacturing processes or assembly.

- Surface Preparation: Position your hanger type shot blasting machines as essential tools for preparing metal surfaces for coating applications such as painting, powder coating, or plating. Emphasize how your machines contribute to achieving superior adhesion of coatings, which enhances the durability and aesthetic appeal of the finished products.

- Deburring: Showcase how your hanger type shot blasting machines are effective in eliminating burrs and sharp edges from metal parts, improving their safety, functionality, and ease of assembly. This capability is crucial for industries where precise and smooth edges are critical for product quality.

- Descaling: Highlight the descaling capabilities of your machines, emphasizing their ability to remove scale and oxidation from metal surfaces. This feature is particularly beneficial in industries like automotive, aerospace, and construction, where surface quality directly impacts performance and longevity.

- Surface Finishing: Demonstrate how your hanger type shot blasting machines enhance the surface finish of metal parts, making them smoother and more aesthetically pleasing. This capability is valuable for manufacturers looking to differentiate their products through superior surface quality.

- Shot Peening: Position your machines as capable of performing shot peening, a process that introduces compressive stresses into metal surfaces to improve fatigue strength and resistance to stress corrosion cracking. Highlight how this capability extends the lifespan and reliability of components in demanding applications.

- Casting and Forging Cleaning: Stress the importance of clean surfaces in casting and forging processes. Showcase how your hanger type shot blasting machines effectively remove sand, scale, and other residues from castings and forgings, ensuring quality and consistency in production.

- Stress Relieving: Highlight how your machines contribute to stress relieving processes, reducing internal stresses in metal parts to improve dimensional stability and performance. This capability is critical in industries where precision and reliability are paramount.

- Paint Stripping and Maintenance Cleaning: Explain how your machines facilitate paint stripping and maintenance cleaning operations, enabling efficient refurbishment and upkeep of industrial equipment and structures. Position your machines as valuable assets in prolonging the service life of metal components.

- Surface Roughening: Describe how your hanger type shot blasting machines create a roughened surface texture on metal parts, enhancing the adhesion of coatings, adhesives, and other surface treatments. This capability ensures robust and durable surface finishes in various industrial applications.

- Customization and Support: Highlight your capabilities as a hanger type shot blasting machine supplier to provide customized solutions tailored to specific customer needs. Emphasize your commitment to customer support, including installation, training, and ongoing service to ensure optimal machine performance and customer satisfaction.

Benefits of Hanger type shot blasting machine

Hanger-type shot blasting machines offer several benefits in various industrial applications:

- Efficient Cleaning: They provide thorough and efficient cleaning of parts, removing rust, scale, and other contaminants from the surface.

- Consistent Results: These machines ensure uniform treatment of parts, maintaining consistent quality and finish.

- Versatility: They can handle a wide range of part sizes, shapes, and materials, making them versatile for different manufacturing needs.

- Reduced Labor Costs: Automation in hanger-type shot blasting reduces the need for manual labor in surface preparation tasks.

- Increased Productivity: By automating the cleaning process, these machines can significantly increase throughput and overall productivity.

- Extended Equipment Life: Regular use of shot blasting can prolong the life of equipment by effectively removing surface corrosion and preparing surfaces for further treatment.

- Environmentally Friendly: Compared to other surface preparation methods, shot blasting produces minimal dust and waste, making it more environmentally friendly.

- Cost-Effective: Despite initial investment costs, the efficiency, consistency, and productivity gains often lead to cost savings over time.

- Improved Surface Adhesion: Shot blasting creates a profiled surface that enhances the adhesion of coatings, paints, and other finishes.

- Safety: Automated operation reduces the risk of operator exposure to hazardous materials and processes, enhancing workplace safety.

Overall, hanger-type shot blasting machines are valued for their efficiency, versatility, and ability to deliver high-quality surface preparation across various industries, including automotive, aerospace, foundry, and metalworking.

Top Manufacturer of Hanger Shot Blasting Machines

Process & System stands as the premier manufacturer of Hanger Shot Blasting Machines in India. Our expertise lies in producing and supplying a wide range of shot blasting equipment, including portable shot blasting machines, tumblast shot blasting machines, swing table type shot blasting machine and automatic shot blasting machines, all offered at competitive prices across India.

Discover our hanger type shot blasting machines at affordable rates in key cities such as Jodhpur, Jaipur, Bhiwadi, Alwar, Faridabad, Gurgaon, Noida, Ghaziabad, Agra, Mumbai, Pune, Kolhapur, Solapur, Chennai, Bangalore, Madurai, Coimbatore, and Kolkata, ensuring top quality and customer satisfaction.

FAQ

Can I integrate a hanger type shot blasting machine into my existing production line?

Yes, hanger type shot blasting machines can be integrated into existing production lines. Customization options are available to ensure seamless integration with your workflow, including automated loading and unloading systems.

What safety measures are in place for operating a hanger type shot blasting machine?

Safety is a priority, and our machines are equipped with multiple safety features, such as:

- Enclosed blasting chambers to contain abrasive materials.

- Interlock systems to prevent operation when doors are open.

- Emergency stop buttons.

- Regular training and safety protocols for operators.

What is the typical lifespan of a hanger type shot blasting machine?

The lifespan of the machine depends on factors like usage intensity, maintenance practices, and operating conditions. With proper maintenance, our hanger type shot blasting machines can last for many years, providing reliable service.

Do you offer after-sales support and spare parts for your hanger type shot blasting machines?

Yes, we offer comprehensive after-sales support, including technical assistance, maintenance services, and a supply of genuine spare parts to ensure your machine operates smoothly.

Can I request a custom design for a hanger type shot blasting machine?

Absolutely. We understand that different industries have unique requirements. We offer custom design solutions to meet your specific needs, ensuring optimal performance and efficiency for your applications.