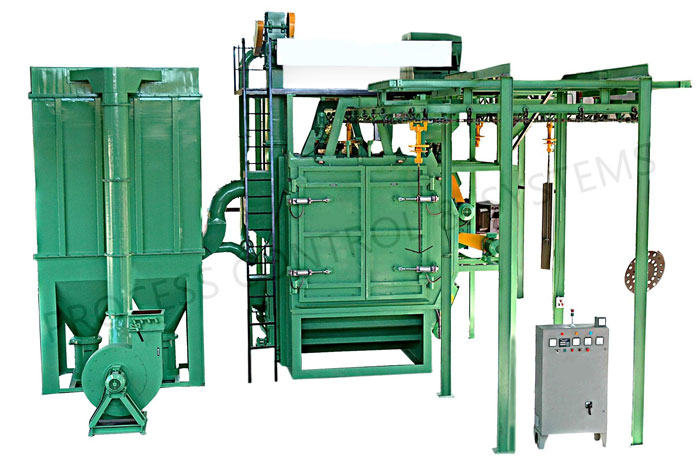

Process & System is a trusted shot blasting machine supplier in Ethiopia, delivering advanced surface preparation solutions tailored for industries across Addis Ababa, Dire Dawa, Hawassa, Mekelle, and Bahir Dar. Our machines are designed to provide high-efficiency cleaning, rust removal, and surface finishing, ensuring superior performance in manufacturing, construction, shipbuilding, and heavy engineering sectors.

With a focus on durability, productivity, and cost-effectiveness, we serve Ethiopia's growing infrastructure, automotive, and energy markets, offering not just machines but complete end-to-end support.

Why Choose Process & System in Ethiopia?

- Global Quality Standards – Built for consistent results and long service life.

- Adapted for Local Industries – Machines suited for construction, steel fabrication, energy, and engineering sectors in Ethiopia.

- Custom Configurations – Tailored machines to handle local raw materials, workpiece sizes, and production demands.

- After-Sales Support – Training, installation, and spare parts available locally.

- Cost-Effective Solutions – Machines designed for high return on investment.

Our Range of Shot Blasting Machines in Ethiopia

We offer a wide variety of shot blasting machines in Ethiopia, each engineered for specific applications.

1. Spinner Hanger Shot Blasting Machine

Best For: Complex or fragile parts requiring precise, collision-free blasting.

Applications in Ethiopia:

- Automotive components (axles, gear housings, chassis parts)

- Agricultural machinery parts

- Pumps and castings

- Engineering spares

Advantages:

- Gentle blasting without damaging parts

- Handles variable batch sizes

Spinner Hanger Shot Blasting Machine

2. Tumblast Shot Blasting Machine

Best For: High-volume batch cleaning of small/medium-sized parts.

Applications in Ethiopia:

- Fasteners and hardware

- Foundry castings and forgings

- Chains, gears, and industrial components

Advantages:

- Compact design for space-limited workshops

- High throughput with minimal operator input

Tumblast Shot Blasting Machine

3. Table Type Shot Blasting Machine

Best For: Large or heavy workpieces that cannot be rotated in tumblers.

Applications in Ethiopia:

- Engine blocks

- Steel slabs and plates

- Pipe fittings

- Dies and molds

Advantages:

- Handles several tons of weight

- Ensures uniform blasting coverage

Table Type Shot Blasting Machine

4. Tunnel Type Shot Blasting Machine

Best For: Inline processing of long, large, or continuous components.

Applications in Ethiopia:

- Structural steel beams

- Bridge parts

- Large pipes for oil & gas

- Wind energy towers

Advantages:

- Fully automated conveyor blasting

- Designed for mass production

Tunnel Type Shot Blasting Machine

5. Portable Shot Blasting Machine

Best For: On-site blasting in construction and marine projects.

Applications in Ethiopia:

- Bridge cleaning and maintenance

- Pipeline preparation

- Construction site surface cleaning

- Tank and silo descaling

Advantages:

- Easy to move and operate

- Ideal for fieldwork in remote locations

6. Airless Shot Blasting Machine

Best For: Large-scale operations where air-based blasting is not feasible.

Applications in Ethiopia:

- Concrete surface cleaning

- Ship deck and hull treatment

- Heavy steel fabrication

- Wind turbine components

Advantages:

- Low operational costs

- Consistent and controlled finish

Airless Shot Blasting Machine

Comparison of Shot Blasting Machines in Ethiopia

| Machine Type | Best For | Key Applications | Indicative Price (ETB) |

|---|---|---|---|

| Spinner Hanger | Complex/fragile parts | Automotive parts, pumps, castings, machinery spares | Br. 3,800,000 - Br. 7,200,000 |

| Tumblast | High-volume small/medium components | Fasteners, castings, forgings, chains | Br. 2,400,000 - Br. 4,200,000 |

| Table Type | Large/heavy workpieces | Steel slabs, engine blocks, dies, pipe fittings | Br. 3,200,000 - Br. 6,500,000 |

| Tunnel Type | Continuous large-scale production | Beams, pipes, ship sections, wind towers | Br. 5,500,000 - Br. 12,000,000 |

| Portable | On-site/field blasting | Bridges, pipelines, tanks, site cleaning | Br. 800,000 - Br. 1,600,000 |

| Airless | Heavy-duty large-scale blasting | Ship decks, concrete, wind turbines, steel plates | Br. 3,900,000 - Br. 9,000,000 |

Industries We Serve in Ethiopia

Our machines are widely used across Ethiopia's key industrial and infrastructure sectors:

- Construction & Infrastructure: Cleaning rebar, beams, prefabricated steel, and bridge sections. Ensures paint/coating adhesion and long-term durability.

- Automotive & Engineering: Shot peening of springs, rust removal on chassis parts, and cleaning engine components. Enhances strength and extends service life.

- Energy & Power Sector: Preparation of wind turbine towers, pipelines, and tanks. Provides corrosion protection for energy infrastructure.

- Oil, Gas & Mining: Cleaning drilling rigs, pipelines, and storage equipment. Portable machines suit Ethiopia's remote mining zones.

- Foundries & Steel Fabrication: Sand removal, rust cleaning, and weld preparation for steel structures. Reduces downtime and improves welding quality.

- Marine & Shipbuilding: Surface treatment of ships, barges, and offshore structures. Prevents corrosion and increases vessel lifespan.

Why Ethiopian Industries Trust Process Control & System?

- Durable equipment that withstands Ethiopia's varied climate.

- Customizable machines for local industrial requirements.

- Strong after-sales support with service, spares, and training.

- Preferred by industries from construction to shipbuilding.

Frequently Asked Questions (FAQs)

Who is the best shot blasting machine supplier in Ethiopia?

Process & System is one of the most trusted shot blasting machine suppliers in Ethiopia, providing durable equipment, installation, and after-sales support.

What types of shot blasting machines are available in Ethiopia?

We supply portable, hanger type, table type, tumble type, continuous, airless, and automatic shot blasting machines to meet different industry needs.

Which industries in Ethiopia use shot blasting machines?

Industries such as construction, automotive, shipbuilding, manufacturing, foundries, steel plants, and oil & gas use shot blasting machines for surface preparation.

Do you provide installation and training in Ethiopia?

Yes, Process & System offers installation, operator training, and maintenance support across Ethiopia to ensure smooth machine operation.

Are spare parts available for shot blasting machines in Ethiopia?

We provide OEM spare parts and consumables to Ethiopian industries for long-term performance and reduced downtime.

How can I order a shot blasting machine in Ethiopia?

You can contact Process & System directly with your requirements, and our team will provide a customized quote, delivery timeline, and technical guidance.

Why should Ethiopian industries choose Process & System over local suppliers?

Our machines offer higher durability, advanced technology, customization, and long-term cost savings, making us a better choice than local alternatives.

Manufacturing Shotblasting machine

Process Control & System is a leading shot blasting machine manufacturer and supplier across the globe. Our major operating states and cities in India include Kolkata (W.B), Gandhinagar (Gujarat), Jodhpur (Rajasthan), Faridabad (Haryana).

Supplier of Shotblasting machine

Process Control & system is a leading manufacturer of Shotblasting machine in India and supplier across the world. Our major places where we export and supply our shotblasting machines include )Abu Dhabi (UAE, South Africa, Kenya, Ethiopia, Zimbabwe.