Vacuum Blaster

All standard models of Portable Abrasive Blaster are available with and without Remote Control Version.

In five standard models having cleaning rates from 3 to 20 sq-meter/hr.Tungsten carbide venturi nozzles in 5mm, 6mm, 8mm, 10mm, 12mm bore. Air requirement varies as per the model from 45 cfm to 250 cfm at 80 psi.

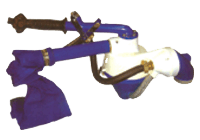

KUBT - 14

- Specially designed model

- Recommended for intermittent blasting & low productivity

Description of Machine

Blast cleaner P-14, with Edge and Angle Cleaning Attachment, 5 Mtr Air Hose with end Coupling and T.C. Nozzle 8mm.

KU - 15RP

- Portable mounted on 4 wheels

- Blasting at high speed & velocity

- Pneumatic recovery system

- Abrasive tank capacity 28 liters

- S. S. Cartridge dust collector

KU - 15RP

- Portable mounted on 4 wheels

- Uniform cleaning and finishing

- Vaccum pump recovery

- Abrasive tank capacity 28 liters

- S. S. cartridge dust collector

| TECHNICAL SPECIFICATION | ||

|---|---|---|

| Mode KU-15RP | Model KU-15RE | |

| (With Pneumatic Recovery) | (With Vacuum Pump Recovery) | |

| Overall Dimensions mm Appx. | 800 x 1100 x 2200 H | 800 x 2000 x 2200 H |

| Abrasive Tank Capacity | 28 Liters | 28 Liters |

| Blast Nozzle TC | 6 mm | 6 mm |

| Blast Hose Dia & Length | 19 mm x 7.5 M | 19 mm x 7.5 M/td> |

| Recovery System | Air Injector | Vacuum Pump/td> |

| Reclaimer Type | Cyclone & Vibrating Screen | Cyclone & Vibrating Screen/td> |

| Dust Collector | S.S. Cartridge | S.S. Cartridge/td> |

| Compressed Air Requirement | 5.10 M3/Min. at 6.33 Kg/sq.cm. | 2.55M3/Min. at 6.33 Kg/sq.cm. |

| Electrical Loading | Nil | 10 HP 415V 1 3P / 50Hz/td> |

Mobile Close Circuit Vaccum Blasting Machine - Model KU-10.

The blasting is accomplished manually by holding the gun against the work surface, which is fairly straight. The equipment being closed circuit, the spent abrasive is sucked due to the vacuum created and cycled into the pressure generator after passing through the reclaimer unit. Thus, the used abrasive and dust created are contained within the equipment, keeping the blasting operation dust free.

Brief Working

Complete equipment/unit of Vacuum Blasting Machine with all accessories, all sub-assemblies accommodated in two frameworks provided with lifting lugs. The machine is suitable for blasting with chilled from grit G-02 to G-39 of BS-2451 and aluminum oxide 14/24-60/80. The machine is capable of reclamation (with a vacuum pump of 15 HP) from 22.8 mtrs. Distance max. A single gun is provided with Supersonic tungsten Carbide for nonferrous abrasive. Proper sieving arrangement with manual rapping of dust collector's filter bags provided with heavy-duty moisture separator to arrest line condensation from compressed air entering into the equipment to keep abrasive dry and blast surfaces uncontaminated to the extent possible.

All the parts of the systems are accommodated on two frameworks with a lifting lug.

The air consumption of the nozzle depends on the size of the nozzle used and the pressure during machine operation.

KU-10

- Portable mounted on 4 wheels

- Blasting at high speed & velocity

- Vaccum pump recovery system

- Abrasive tank capacity 112 liters

- S. S. Cartridge dust collector

- Single Gun outlet

| TECHNICAL SPECIFICATION | Model KU-10 |

|---|---|

| Overall Dimensions mm Appx. | 1600(L) X 2500(W) X 3600(H) |

| Abrasive Tank Capacity | 112 Liters |

| Blast Nozzle TC | 9.5 mm |

| Blast Hose Dia & Length | 25 mm x 15 M |

| Recovery System | Vacuum Pump |

| Reclaimer Type/td> | Cyclone & Vibrating Screen |

| Dust Collector | Cartridge Type |

| Compressed Air Requirement | 7.5 M3/Min at 6.33 Kg/sq.cm |

| Electrical Loading | 15 HP 415V / 3P / 50 Hz |

Mobile Close Circuit Vaccum Blasting Machine - Model KU-15C

KU-15C

- Portable mounted on 4 wheels

- Uniform cleaning and finishing

- Vaccum pump recovery

- Two Gun outlet

| TECHNICAL SPECIFICATION | Model KV-15C |

|---|---|

| Overall Dimensions mm Appx. | |

| (a) Reclaimer | 2000 mm(W) x 2000 mm(D) 3600 mm(H) |

| (b) Dust Collector | 2000 mm(W) x 1600(D) 3200 mm(H) |

| Abrasive Tank Capacity | |

| (a) Upper Tank | 30 Liter |

| (b) Lower Tank | 60 Liter |

| Blast Nozzle TC | 9.5 mm x 2 Nos. |

| Blat hose Dia & Length | 25 mm x 15 Mtr. 2 Nos. |

| Recovery System | Vacuum Pump |

| Reclaimer Type | Cyclone & Vibrating Screen |

| Dust Collector | Cartridge Type |

| Compressed Air Requirement | 15 M3/Min at 6.33 Kg./Sq.cm. |

| Electrical Loading | 30 HP 415 V / 3P / 50 Hz |