New Blast Wheels

New Blast Wheels

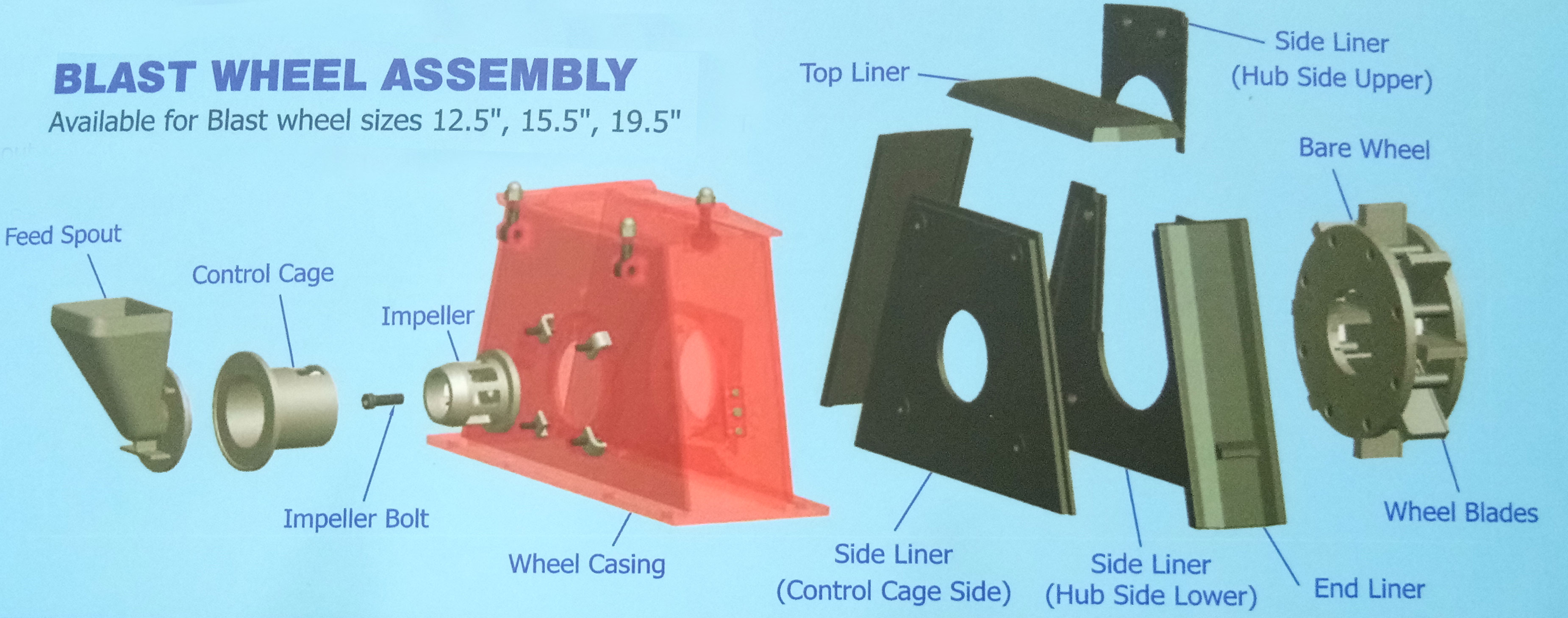

A new Blast Wheel with a direct or indirect drive system is provided. Wheel assembly constitutes various liners manufactured out of the best alloy steel for optimum life. The per horsepower abrasive throwing capacity is optimal & maintenance assembly is operators friendly.

It entails Control Cage having an optimized opening for giving per HP a more abrasive throw capacity and a longer blasting pattern with a wider hot shot. The Control Cage, Impeller, and Blade Set are Shell Casting / Investment Casting with Hi Moly Hi Chrome Alloy Steel Composition and are subjected to a specialized heat treatment process for better and uniform higher hardness of 65-68 HRC.

All Side Liners are made of Hi Mn Steel and properly heat treated. A special resetting Guide Dial is provided for the repeated correct setting of the Control Cage.

The Blades are self-locking type and can be easily removed/replaced. All the parts of the Wheel Assembly are easy to replace and User/Maintenance friendly.